PRODUCT / SERVICES

DOWNDRAFT BOOTH

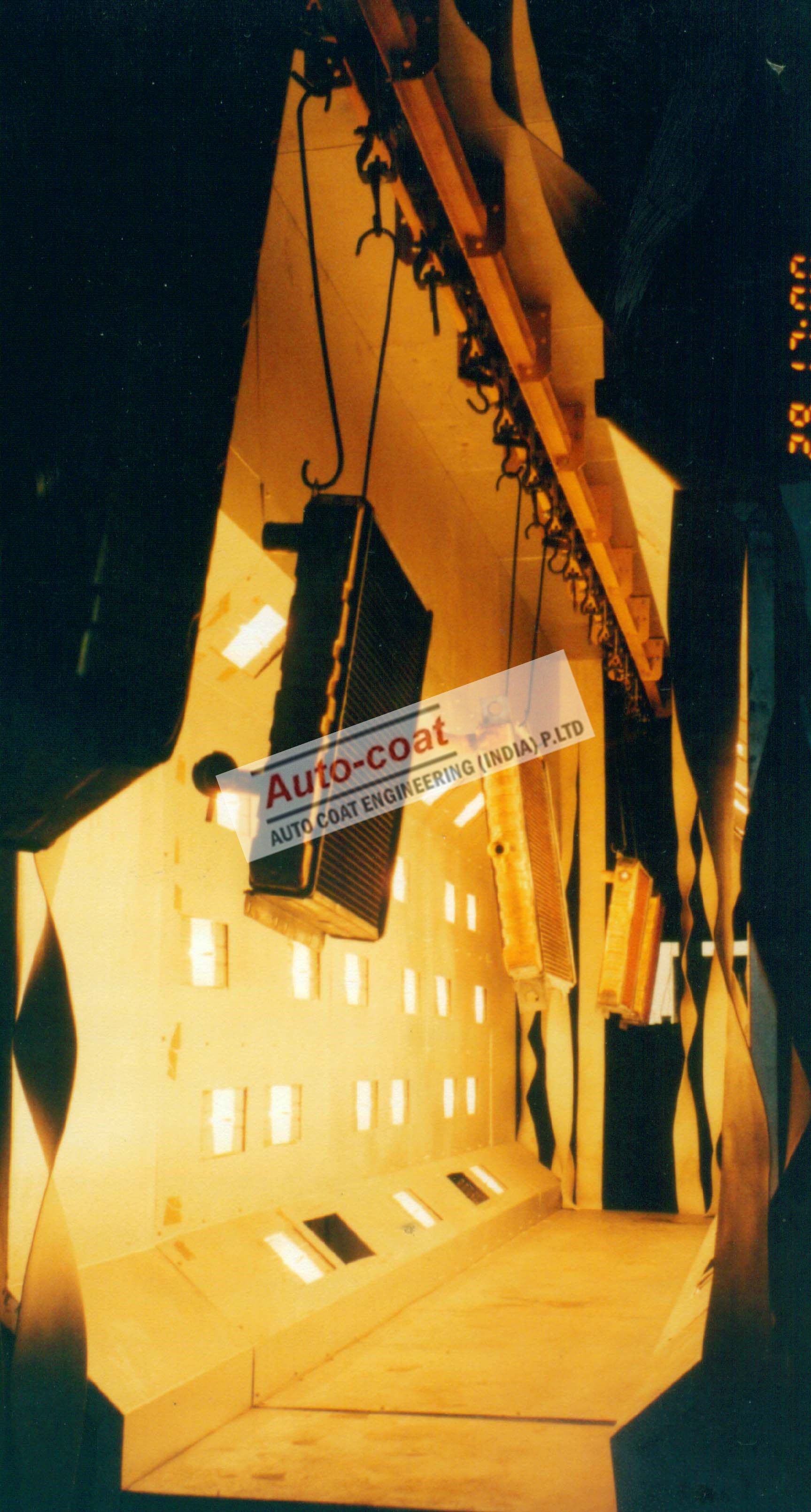

Autocoat Downdraft Paint Booth are specially used for painting of heavy parts and large components, which are difficult to handle namely, wagons, earth moving machineries, chassis of vehicles, trailers, etc. In a DOWNDRAFT BOOTH air flows from top to bottom. And Air Draft is towards ground or to the exhaust chamber.

The Wet Downdraft Spray Booth can be single sided or double sided extraction chamber depending on the size of the component. Painter goes around the component to paint all sides

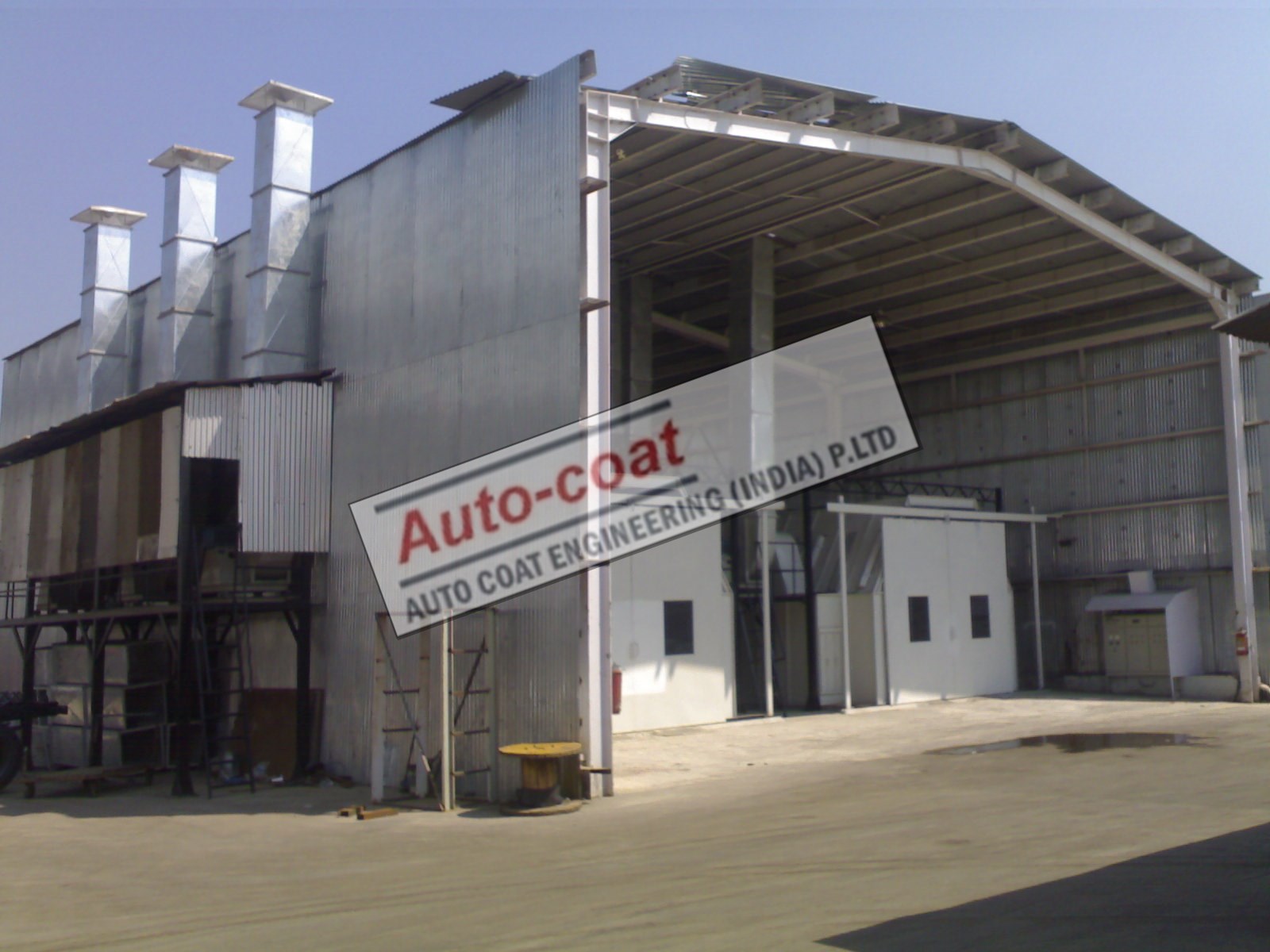

LARGE PAINT BOOTH

Autocoat Large Paint Booth is designed with the Side Draft Air flow (for medium sized component) is popular because of lower initial cost & lower operating cost.

Dry Type Large Paint Booth is ideally suitable for low volume production in which component or product can be rotated with the help of EOT Crane or underground turntable. & generally open type. Dry Type Large Spray Booth is more popular with handling with EOT Crane or with floor trolley & generally Open Type is suitable for industria

PAINT HEATING OVEN (PAINT CURING OVENS OR PAINT BAKING OVEN)

Paint Drying Ovens, also referred to as Dryers or Paint Curing Ovens or Paint Baking Oven removes the moisture from water-based coatings and adhesives. Paint Drying Ovens are also removes water from the surface or interior of products with the help of thermostatic controls in case of electrical heating and temperature controllers operating solenoid valves in case of steam, gas and oil heating.

A Industrial Paint Curing Oven cures dries the paint through the heated air that is re circulated

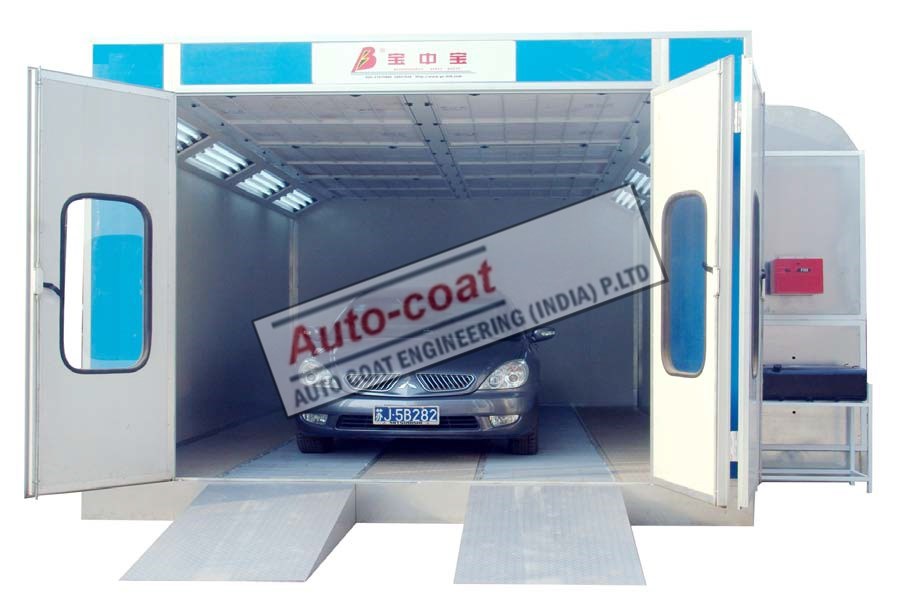

AUTO PAINT BOOTH (Spray Booth cum Oven, Garage Paint Booth, Paint Booth Heating System, Paint Baking

Autocoat Engineering offers precision engineered range of Auto Paint Booth (Car refinishing Booth) widely used for the of spray painting and immediate drying of Automobile. AUTO PAINT BOOTH increases cleanliness and operator efficiency, making it suitable for a number of application, large sized products, and other industries and fulfils pollution norms.

Autocoat has tied up with the M/s Guangdong Jingzhongjing from China who has wide & exhaustive experience in manufacturing of Car refinishi

Paints, Powder & Varnishes

We are provided spray paint booth, painting booth, conveyorised powder coating booth, industrial ovens, pre treatment plants, downdraft booths, spray booths cum oven etc.

PAINT BOOTH MADE IN CHINA

Autocoat Engineering (I) Pvt. Ltd. is already in manufacturing of painting plant on Turn Key Basis having supplied many large Spray Painting Booth & Conveyorised Phosphating & Painting plant all over India, For low volume production, ideal setup is combination of Spray painting & drying operation in single equipment known as Spray Bake System or Spray Booth with Heating. (Paint Booth Made In China)

Guangdong Jingzhongjing Jingzhongjing Industrial Painting Equipment Co., Ltd, is a Large reput

Paint Booth,Spray booth , Spray Painting Booth,Downdraft Booth

Paint Booth,Spray booth , Spray Painting Booth,Downdraft Booth,Dust Free Painting,Auto Painting Machine,Pretreatment Plant,Turnkey Paintshop,Powder Coating Booths,Powder Coating Plant,Oil Booth,Gelcoat Booth,Conveyorised Painting,Paint Curing Ovens,Dry Back Booth,Water Wash Booth,Infrared Oven.

Miscellaneous Industrial & Engineering Goods & Supplies

We are provided spray paint booth, painting booth, conveyorised powder coating booth, industrial ovens, pre treatment plants, downdraft booths, spray booths cum oven etc.

LAB BOOTH (LABORATORY BOOTH)

Autocoat has designed & developed wide series of LAB BOOTH designed to fulfill stringent pollution norms as well as with amazingly low running cost. Autocoat is Manufacturer & Exporter of LABORATORY BOOTHS.

Autocoat Lab Paint booths are built to last: with the quality appearance, 100% assembly & Trials in-house ensure guarantied performance as well as at customers place. Autocoat computer generated labels & lamination, detailed drawings and well documented Manual will save you time and money

Spray Paint Booths

Autocoat Engineering is specialized in the manufacturing of all kinds of Spray Booth standard or customized, suitable for batch or conveyorised application for small or very large component.

Many Satisfied customers in India are using Autocoat Spray Paint Booth because of superior designing & selection of bought out items (Design is most critical). All Products are manufactured, Assembled & Tested for performance before dispatch and & commissioned at site. Training, after sale service & special

Gel Coat Booth (Gel Spray Booth, Gelcoat Paint Booth)

Gel coat booths are newer application of spraying Gel coat, widely used for spraying on moulds.

Gel coat is a material used to provide a high-quality finish on the visible surface of a fiber-reinforced composite material. The most common gel coat is based on epoxy or unsaturated polyester resin chemistry. Gel coats are modified resins which are applied to moulds in the liquid state.

Gel Coat Booth and Gel Spray Applications

Gel Spray Booth application:

Gel coat is application used in maj

OIL SPRAY BOOTH (OIL BOOTH)

OIL BOOTH is newer application of spraying oil instead of dip-oiling .OIL BOOTH are necessary for automobile parts or other components to spray oil in an enclosed chamber to protect them from “Temporary corrosion “ i.e. prevention of components say for 30 days or 60 days or more”

In OIL BOOTH, high powered exhaust system to carry excess sprayed oil is exhausted to reduce TLVC (Threshold Limited Value) and thus will reduce fire hazard and can give operator comfort for breathing.

Secon

REVAMPING PAINTING PLANT / MODIFICATION PAINTING PLANT (RENOVATION OF EXISTING PAINTING PLANTS)

Autocoat Engineering is the most experienced Painting Plant Manufacturer in India since last 35 years. Autocoat Engineering has been supplier SHIFTING PAINTING PLANT or DISMENTALING PAINTING PLANT among other valuable products.

We have wide experience of manufacturing UPGRADATION PAINTING PLANT / MODIFICATION PAINTING PLANT or RENOVATION OF EXISTING PAINTING PLANTS with different material handling and different product size, and different production volume.

Why do you need to “Upgrad

INFRARED TYPE OVEN (INFRARED OVEN SYSTEM)

Powder Curing Ovens designed to cure or dry water based or high solid stains, sealers, and top-coats. High velocity flash off sections enhances the curing process. Engineered to fit over your existing conveyor or built as an integral part of your new finishing system, drying tunnels are economical, reliable, easy to install.

ADVANTAGES OF INFRARED OVEN SYSYEM :

• Production speed

• Space considerations

• Presentation of parts

• Control

• Capital costs and maintenance

• the

PAINT BOOTH

Autocoat Engineering is specialized in the manufacture of all kind of Paint Booth and painting booths. Featuring various booth models and specializing in custom designs for unique Paint Booth applications, our flexible, state-of-the-art Paint Booths may be used for production Batch finishing as well as high production finishing on a Large Conveyor Line.

PAINT BOOTH has been advocated through out industry as the most efficient method of filtering paint over spray. At the same time Paint Booth

LARGE PAINT BOOTH

Autocoat Large Paint Booth is designed with the Side Draft Air flow (for medium sized component) is popular because of lower initial cost & lower operating cost.

Dry Type Large Paint Booth is ideally suitable for low volume production in which component or product can be rotated with the help of EOT Crane or underground turntable. & generally open type. Dry Type Large Spray Booth is more popular with handling with EOT Crane or with floor trolley & generally Open Type is suitable for industria

DINITROL PAINT BOOTH

DINITROL-: Dinitrol is a thixotropic rust preventive fluid which provides long term resistance against corrosion and abrasion, even under severe conditions. Provides a tough elastic waxy protective coating. Dinitrol leaves a brown, waxy water repellent protective film. Super penetrating corrosion prevention. Stops existing rust. DINITROL has a high penetrating ability, which penetrates thick layer of rust and in cavity.

DINITROL PAINT BOOTH is known as Dinitrol Spray Booth or Dinitrol Painting

AUTOMATIC PAINTING SYSTEM (Automatic Painting Machine)

Autocoat Engineering (I) Pvt. Ltd. is already in manufacturing of painting plant on Turn Key Basis having supplied many large Spray Painting Booth & Conveyorised Phosphating & Painting plant all over India, Bahrain, Dubai, Saudi Arabia, Egypt etc.

To increase productivity, reduce cost of painting, Automatic Spray Painting System are designed, developed in Japan, Taiwan & China and are extremely popular resulting competitive products. Autocoat is now offering great opportunities to Indian man

SIDE DRAFT BOOTH (Or Side Draft Paint Booth, Side Draft Spray Booth, Side Draft Painting Booth)

What is Side Draft Booth..??

As per OSHA Standards effectiveness of the Side Draft Paint Booth is dependent upon air draft in the direction of spray painting by painter is inside the Side Draft Paint Booth. So in a Side Draft Paint Booth open from front side air draft moves towards exhaust chamber & thus over sprayed particle (paint particle) moves towards exhaust chamber along with direction of air draft.

So it has to be always remembered that in the Side Draft Painting Booth, Component wi

.jpg)

DUST FREE SPRAY PAINTING (Or Dust Free Painting Booth, Plastic Painting Booth)

Dust Free Paint Booth can be also termed as Dust free painting.

Dust is one of the major problems in all modern paint shops and these can be a serious issue resulting higher rejection. In India, due to Dusty Environment & poor equipment design & poor process selection & lack of housekeeping as well as maintenance. Rejection due to dust in painting is higher & higher beyond imagination. Recurring rework cost for rejected component due to dust in paint shop is a major headache.

DUST FREE PAIN

POWDER COATING PLANT (POWDER COATING BOOTH, POWDER COATING SYSTEM, CONVEYORISED POWDER COATING)

Powder coating technology that has made a major impact in the finishing industry. The POWDER Booth finish is fast replacing liquid and plated finishing for a variety of reasons.

Advantages of POWDER COATING

1. No primer necessary: Powder Coating is a single coat process.

2. Less manpower: Powder Coating gives advantage faster productions, no mixing, unskilled application technique, very little equipment maintenance required.

3. Environmental : in powder Coating there is no solvent p

CONSULTANCY PAINTING PLANT (COMPREHENSIVE)

All Audits are designed to find out the present as well as potential problems in a Paint Shop. The Audit Report specifies the deviations in the Paint Shop performance with respect to the designed parameters. Based on the report, an action list can be drafted, which will help in taking necessary steps for the trouble free operation of the Paint Shop at the designed efficiency. Audits can focus on addressing current issues and suggest improvements, will comprise of

Pre-treatment or Phospha

WATER BOOTH (Or Water Paint Booth, Water Spray Booth, Water Type Paint Booth, Water Wash Paint Booth

The WATER WASH SPRAY BOOTH provides an extremely efficient means of removing paint particles from the exhausted air by using water as a filtration media; we have designed the WATER WASH SPRAY PAINTING BOOTHS for many finishing applications.

We also offer both pump as well as no-pump versions in open type model, enclosed type model and conveyorised models. Standard WATER WASH SPRAY PAINTING BOOTHS are utilized for high volume paint usage, medium or large sized components and batch processes.

PRETREATMENT PLANTS (PRETREATMENT SYSTEMS) PHOSPHATING PLANT SPRAY PRETREATMENT PLANT, DIP PRETREAT

Pretreatment plants & pretreatment systems can be defined as a brooder area of pre-cleaning process , here the basic theory of pretreating the component remains the same but with addition of modernization and sophisticated methods.

Pretreatment systems are normally used for high production facilities where number of different components or jobs need to be pre-cleaned and the sent for powder coating or painting. Life of a component basically depends on how clean is the component before it sent

Tell Us What You Are Looking For?

SIGN IN TO MYEIB